|

Grade |

Ni |

Cr |

Fe |

Mn |

C |

Cu |

Si |

S |

Al |

Ti |

Mo |

|

Alloy 825 |

38.00-46.00 |

19.50-23.50 |

≥22.00 |

≤1.00 |

≤0.05 |

1.50-3.00 |

≤0.50 |

≤0.03 |

≤0.20 |

0.06 -1.20 |

2.50-3.50 |

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 Chemical Composition

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 Mechanical Properties

Grade

Condition

Tensile Strength ksi(MPa)

Yield Strength ksi(MPa)

Elongation(%)

N08825

Annealed

≥85(586)

≥35(241)

≥30

N08825

Hot finished annealed

≥75(517)

≥25(172)

≥30

N08825

Cold-worked annealed

≥85(586)

≥35(241)

≥30

N08825

Hot-forming quality

-

-

-

|

Grade |

Condition |

Tensile Strength ksi(MPa) |

Yield Strength ksi(MPa) |

Elongation(%) |

|

N08825 |

Annealed |

≥85(586) |

≥35(241) |

≥30 |

|

N08825 |

Hot finished annealed |

≥75(517) |

≥25(172) |

≥30 |

|

N08825 |

Cold-worked annealed |

≥85(586) |

≥35(241) |

≥30 |

|

N08825 |

Hot-forming quality |

- |

- |

- |

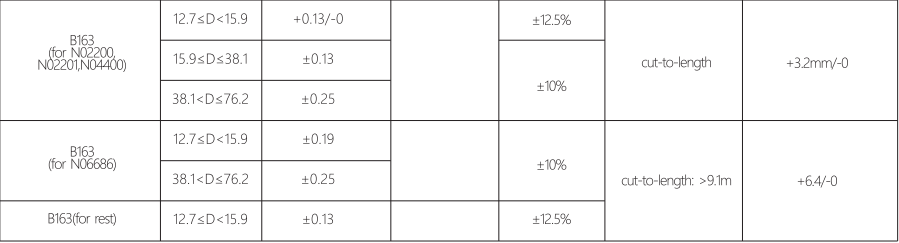

The ASTM B163 Nickel alloy seamless tube and pipe tolerance

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 APPLICATIONS

Alloy 825 is widely used in oil and gas applications. Other uses include chemical process equipment, exhaust systems, and power generation. CRA offers specialty alloy 825 seamless pipe & tube for use in multiple industries and applications, including:

- Corrosive well conditions containing the presence of CO2 , H2S, and chlorides, in temperatures up to 300°F, without the presence of sulfur

- Tubing, Casing, & Liners

- Base Pipe for Sand Screens

- Swell Packers

- Exhaust Systems

- Chemical Processing

- Power Generation

- Geothermal

- Carbon Capture & Sequestration (CCS)

One of our Services--Testing

- EN 10204/3.1B, EN 10204 3.1 and EN 10204 3.2 Material Test Certificates (MTC)

- Raw Materials Certificate

- 100% Radiography Test Report

- 100% PMI

- Heat Treatment Charts

- Third Party Inspection Report

- Surface roughness and size measurement

- Manufacturer Test Certificate( Impact Testing, Flatten, Spin,Curve, Hardness, Intergranular ,Point corrosions, Grain size, ET,UT, HT...)

- Laboratory Test Certificate from Govt. Approved Lab

- ..............

One of our Services--End of Pipe and Tube

- BE : Beveled end

- BBE : Bevel both ends

- BLE : Bevel large end

- BSE : Bevel small end

- TOE / POE = Treaded One End / Plain One End

- TOE / BOE = Treaded One End / Beveled One End

- POE / BOE = Plain One End / Beveled One End

- TBE = Treaded Both Ends

- PBE = Plain Both Ends

One of our Services--Packing

- Ply Wooden Boxes

- PE Fabric Bundles

- Standard seaworthy export packing

- Plastic Bags, or as required

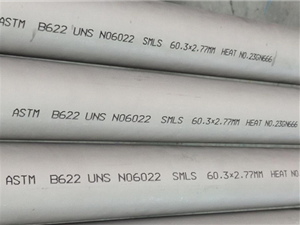

One of our Services--Marking

- Supplier / Manufacturer Name or Custom Logo - on request

- Specification

- Material Grade

- Nominal Size

- Schedule or Wall Thickness

- Method of Manufacturing (Seamless or Welded)

- Heat Number

Marked Pipe Sample: XTD ASTM B163 UNS N08825 SEAMLESS 42.2x 3.56*6000MM HEAT NO. 2023121205A15

Nickel Alloy 825/ N08825/ 2.4858/Incoloy 825/ NA16/NCF825 Material Summary

In the oil and gas industry, the two most important nickel alloys are Inconel 625 and Incoloy 825. lncoloy 825 is an austenitic nickel-iron-chromium-molybdenum-copper alloy containing high levels of chromium, nickel, copper, and molybdenum to provide high levels of corrosion resistance to both moderately oxidizing and moderately reducing environments. This balance of alloying elements grants this alloy exceptional resistance to both chloride stress corrosion cracking, as well as crevice corrosion and general corrosion. It is the high level of nickel in combination with the amount of molybdenum and copper in this nickel alloy produces substantially improved corrosion resistance in a corrosive environment such as reducing environments compared to stainless steel. The addition of titanium in this alloy also helps to stabilize the alloy against intergranular corrosion. Chloride stress corrosion cracking is a type of localized intergranular corrosion on materials that are put under tensile strength, in high temperatures and in an environment that includes oxygen and chloride ions such as seawater.

As an austenitic, nickel alloy, the material is ductile over a wide range of temperatures from cryogenic to well more than 1000 °F (538 °C). Fabricability is typical for a nickel alloy, with the material readily formable and weldable by a variety of techniques.